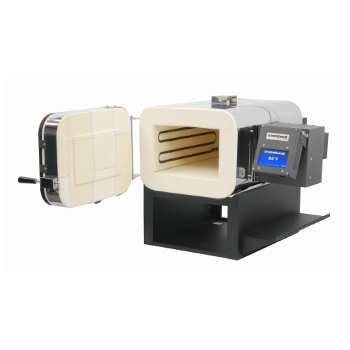

FRONT LOADING KILNS / OVENS

Front-load kilns offer the best of convenience! In front-loading heat-treating kilns, you have concentrated heat on the sides of a narrow tube. The heat is just where you need it! In front loading glass kilns, you have the advantage of being able to load complicated constructions directly onto the shelf at hip level and are able to manipulate hot construction more easily without a rush of hot air coming directly at you.

You'll get the volume of a top loader and the convenience of a front loader. Front-loaders offer easier access to projects within the kiln. In glass models, whether its loading drip crucibles for castings, drying molds, deep drops, multi-stage slump molds, or other projects, front loaders reign supreme. In ceramics and pottery, loading from back to front makes it much easier to position pieces and parts for the best heat penetration.

No matter your height or the depth of your kiln, a front-loader can have some great add-ons that make working on any medium easier. You can add elements on the door and roof that consolidate heat, just like top loaders! It really is the best of both worlds!