Your cart is currently empty.

PRODUCT DESCRIPTION

Product Specifications

| Model: | Evenheat HT-1 |

| Inside Dim: | 13" (width) x 13.5" (height) x 13.5" (depth) |

| Outside Dim: | 24" (width) x 27.5" (height) x 19" (depth) |

| Max Temp: | 2000° F |

| Voltage: | 240 volts |

| Amperage: | 18 amps |

| Watts: | 4,320 watts |

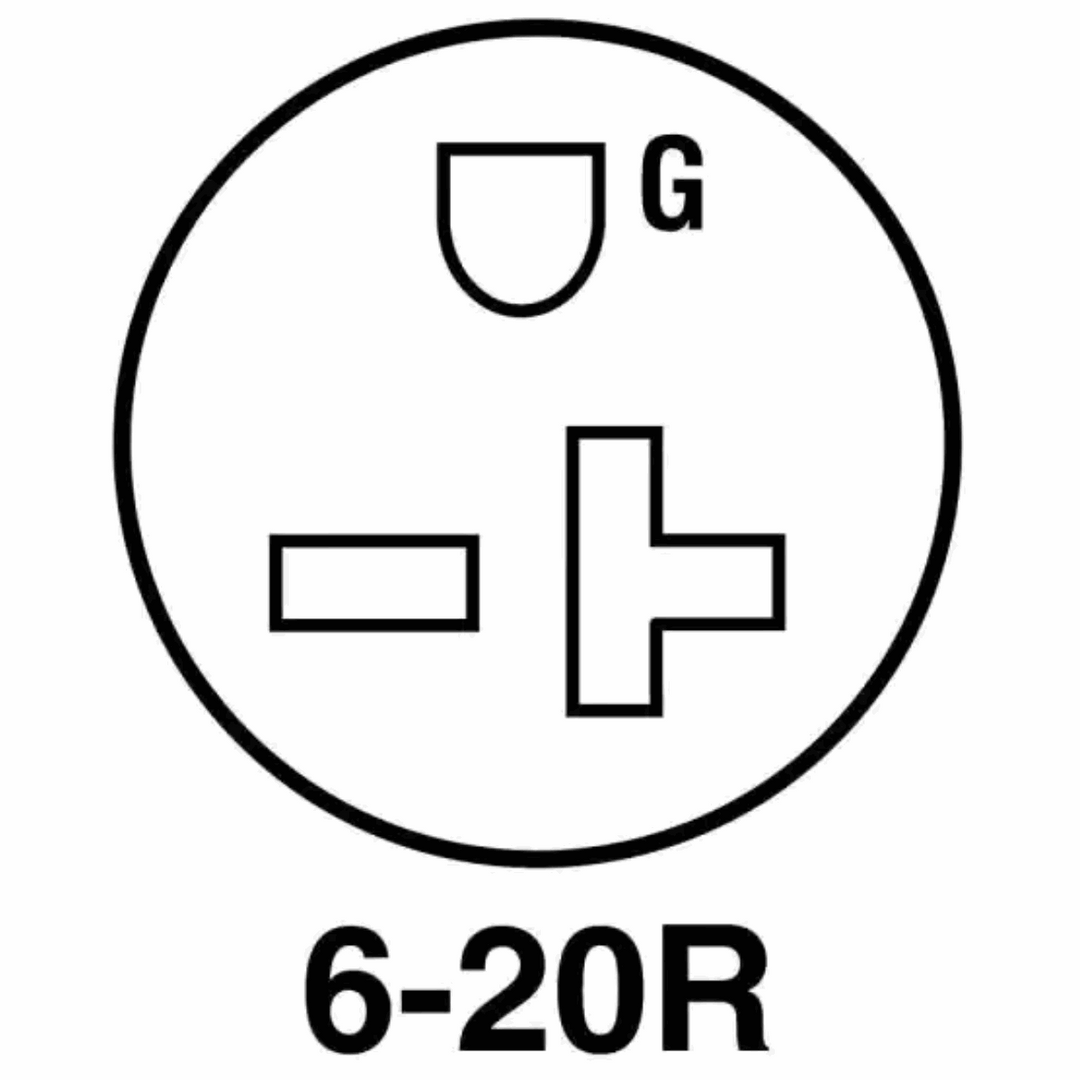

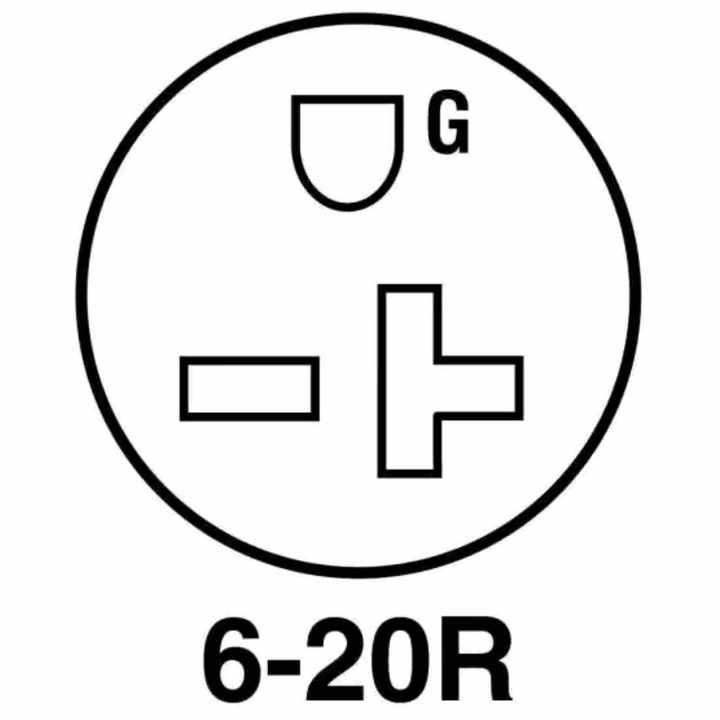

| Receptacle: | 6-20R |

| Ship Wt: | 125# (freight) |

What's Included

Key Information

Warranty Benefits

Enjoy Peace of Mind

Simple, hassle-free product protection for the products you love.

Protection Plan Coverage & Benefits

Frequently Asked Questions:

All About Kilns

What other features are important?

Kilns from every manufacturer are configured with features that allow for different types of functions. These features are available in fiber and brick models. Consider these options:

Top Load Kilns: Ideal for jewelry makers and projects involving powders and frit. Provides good visibility but may be challenging if you’re looking for a deeper kiln or have shorter arms.

Front Load Kilns: Suitable for tasks like enameling and hot manipulations. Offers control and less direct heat, but can be more expensive and require some lifting. This is also true for the weight on the shelf and placing it in front of you.

Clam Shell Kilns: Combines top and front loading, these types of kilns really delivers the best of both worlds; accessibility and free access to your shelf, in addition to ease of loading, and convenience, but may come at a higher cost.

Flip Doors (aka; Punty Doors, Bead Doors, Doggie Doors): Essential for preheating rods and quick bead placement. However, they may affect efficiency and temperature reach.

Windows (aka; quartz portholes): These are not the same as vent holes or peep holes. Optional quartz portholes for monitoring projects at peak temperatures, especially helpful for slumping, draping, or drop ring project. A window will also allow you to check the progress of a pot melt/aperture pour or screen melt.

Top Load Kilns: Ideal for jewelry makers and projects involving powders and frit. Provides good visibility but may be challenging if you’re looking for a deeper kiln or have shorter arms.

Front Load Kilns: Suitable for tasks like enameling and hot manipulations. Offers control and less direct heat, but can be more expensive and require some lifting. This is also true for the weight on the shelf and placing it in front of you.

Clam Shell Kilns: Combines top and front loading, these types of kilns really delivers the best of both worlds; accessibility and free access to your shelf, in addition to ease of loading, and convenience, but may come at a higher cost.

Flip Doors (aka; Punty Doors, Bead Doors, Doggie Doors): Essential for preheating rods and quick bead placement. However, they may affect efficiency and temperature reach.

Windows (aka; quartz portholes): These are not the same as vent holes or peep holes. Optional quartz portholes for monitoring projects at peak temperatures, especially helpful for slumping, draping, or drop ring project. A window will also allow you to check the progress of a pot melt/aperture pour or screen melt.

What to consider when buying a kiln?

What kind of projects would you like to do?

The type, size, and kiln features you require are determined by the projects you choose. This covers things like firing techniques, loading systems, building components, voltage, controllers, and more. Your response may help to clarify your preferences, but you should also consider how well your preferences match with your current circumstances.

Where will you be locating the kiln?

The kind, dimension, and features of your kiln are influenced by where it is. Environment, power supply, safety, and space availability are all important considerations. Your desires might not always line up perfectly with the constraints of your surroundings, this is where we as artists must become creative problem solvers in an effort to overcome our environmental constraints.

We're here to support you. Please reach out if you need any additional advice!

The type, size, and kiln features you require are determined by the projects you choose. This covers things like firing techniques, loading systems, building components, voltage, controllers, and more. Your response may help to clarify your preferences, but you should also consider how well your preferences match with your current circumstances.

Where will you be locating the kiln?

The kind, dimension, and features of your kiln are influenced by where it is. Environment, power supply, safety, and space availability are all important considerations. Your desires might not always line up perfectly with the constraints of your surroundings, this is where we as artists must become creative problem solvers in an effort to overcome our environmental constraints.

We're here to support you. Please reach out if you need any additional advice!

Where should I place my kiln?

Here are some basic guidelines about locating your kiln:

- Make sure you have adequate space... at least 12 - 18 inches of space between the kiln and the wall. (However, for operator comfort, allow room to walk around the kiln if maintenance is required.) It is recommended that the unit be placed on a stand on top of flame-resistant flooring like a cement floor or board.

- Make sure the area is really clean - remove all flammable or combustible materials such as curtains, plastics, rags, paper, packing materials, etc. from the area surrounding the kiln.

- Make sure the area is well ventilated – proper air exchange is necessary for you kiln to last a long time. Heat from the kiln and outside air can accumulate in restricted areas above both gas and electric kilns.

- Make sure that the heat has somewhere to go, and is replaced by fresh cooler air. Set up a fan near the area, or open a window to ensure good air exchange. Check all local requirements or codes before installation.

IMPORTANT: Always read your owners manual and follow you kiln manufacturer's instructions.

Plugs & Electricity

What type of plug do I need?

Each kiln model described on our website will identify which of the following power supply receptacles is used with that model. They are identified by voltage and amperage as well as the NEMA designation. Those described as "direct wire" do not use a receptacle, instead, they are permanently wired.

Maintenance

Care and Maintenance

Proper kiln maintenance is essential for preventing downtime and costly repairs. Here's a checklist to help you keep your kiln in top shape:

Before Every Firing:

Regular maintenance will help your kiln perform efficiently and extend its lifespan.

Before Every Firing:

- Inspect: Check inside your kiln for any unwanted visitors, moisture, or debris. Ensure your pet-friendly area is clean to prevent odorous surprises.

- Vacuum: Turn off the power and use a vacuum with a HEPA filter to clean the interior, removing dust and residue that could affect your glass during firing.

- Clean: Remove flammable materials from the area around the kiln.

- Inspect Elements: Ensure coils/elements are in place, free of debris, and securely fastened. Check thermocouples and tighten lid screws as needed.

- Check for Cracks: Examine your shelf for cracks and address them to prevent issues during firing.

- Power Up: Turn the power back on and ensure the kiln registers the correct room temperature.

- Lid Check Up: Periodically tighten the lid band as the lid expands and contracts during firings. Most kiln lids are manufactured with a protective coating on the "hot side" or inside. This coating was applied to optimize the heat insulation of the lid, as well as to prevent brick dust from falling into the kiln. Address cosmetic lid cracks, and for structural issues, consult the manufacturer during the warranty period. If you are in the warranty period, DO NOT ATTEMPT TO REPAIR THIS without calling the manufacturer, as this could void your warranty.

- Body Check Up: The only things inside of your kiln should be your elements, pins, brick, kiln furniture/posts and kiln washed shelves. Remove any non-essential materials such as (glaze, slip, clay, glass, silica sand) from the sidewalls to protect them and the heating elements. Be cautious when using kiln cement to repair cracks, and contact the manufacturer if needed during the warranty period. If you are in the warranty period, DO NOT ATTEMPT TO REPAIR THIS without calling the manufacturer, as this could void your warranty.

- Inspect Elements: Look for signs of wear such as rust, bulging, or thinning/thickening areas. Elements wear out with usage and may need replacement. If you find it necessary to change out your elements, make sure you speak to the manufacturer to determine the appropriate element size for your kiln. Please refer to your operator’s manual for the discussion and photo's of "Element Replacement".

- Electrical Check Up: Regularly examine the power cable, receptacle, and plug for discoloration, heat, corrosion, or loose connections. Address any electrical issues promptly, and consult the manufacturer if needed, especially during the warranty period. If you are in the warranty period, DO NOT ATTEMPT TO REPAIR THIS without calling the manufacturer, as this could void your warranty.

Regular maintenance will help your kiln perform efficiently and extend its lifespan.

What are Safety Precautions?

Kilns are as safe as any other electrical appliance when used under normal and proper operating conditions. All kiln safety precautions should always be observed.

- Use common sense while installing and using your kiln.

- Do not install your kiln closer than 12" from any surface, or closer than 18” from a combustible surface. Remove all potentially combustible materials from the kiln area.

- Make sure all electrical specifications are followed. Use correct voltage, wire size and circuit breaker. Make sure all connections are tight. Avoid using aluminum wire. Always use the proper grounded receptacle. A qualified electrician or service person should be used for all electrical service or repairs.

- Install in covered, walled in, well-ventilated area. Fumes from the ware should be vented to the outside.

- Avoid moisture. Do not allow your kiln to get wet. Never use your kiln outside!

- Always keep children and unsupervised personnel away. Surface will get hot and a burn could result.

- Fire glass only to the manufacturers recommended firing temperature. Improper fire temperatures could result in damage to your kiln. Do not operate glass kilns over the maximum temperature rating.

- Replace any worn or defective parts with ONLY genuine replacement parts.

- Unplug kiln when not in use and if there is an electrical storm.

- Unplug the kiln before servicing or vacuuming.

- Do not drop or slam the lid shut.

- Let the kiln cool to room temperature before opening the lid.