ANNEALING KILNS

Annealing is the process of slow cooling heated glass through the annealing zone to prevent the presence of internal stress. The appropriate cooling curve varies with glass type and formed shape, especially thickness. This is done between the cooling of the glass from 1100°F down to 300°F. A proper glass annealing oven is critical in glassmaking, as glass that is allowed to cool too quickly will break as it cools, or it will be highly strained when it reaches room temperature and liable to be brittle and break easily. If glass is not properly annealed, it is likely to break during the cooling phase or at a later date.

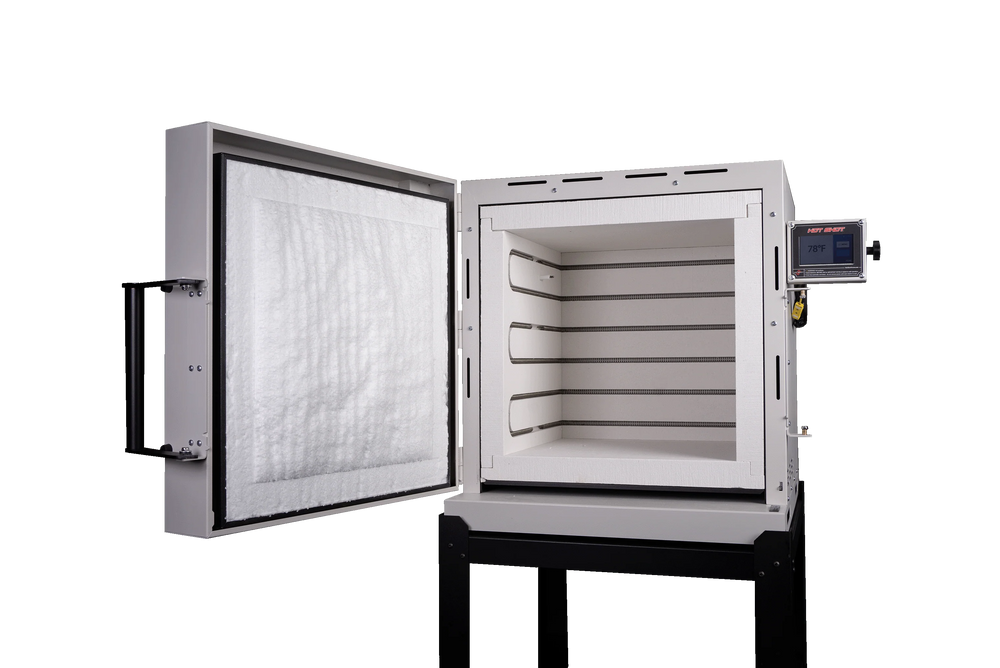

Our annealing kilns and ovens have convenient flip doors and easy access guillotine doors to give you one handed access to the inner chamber.