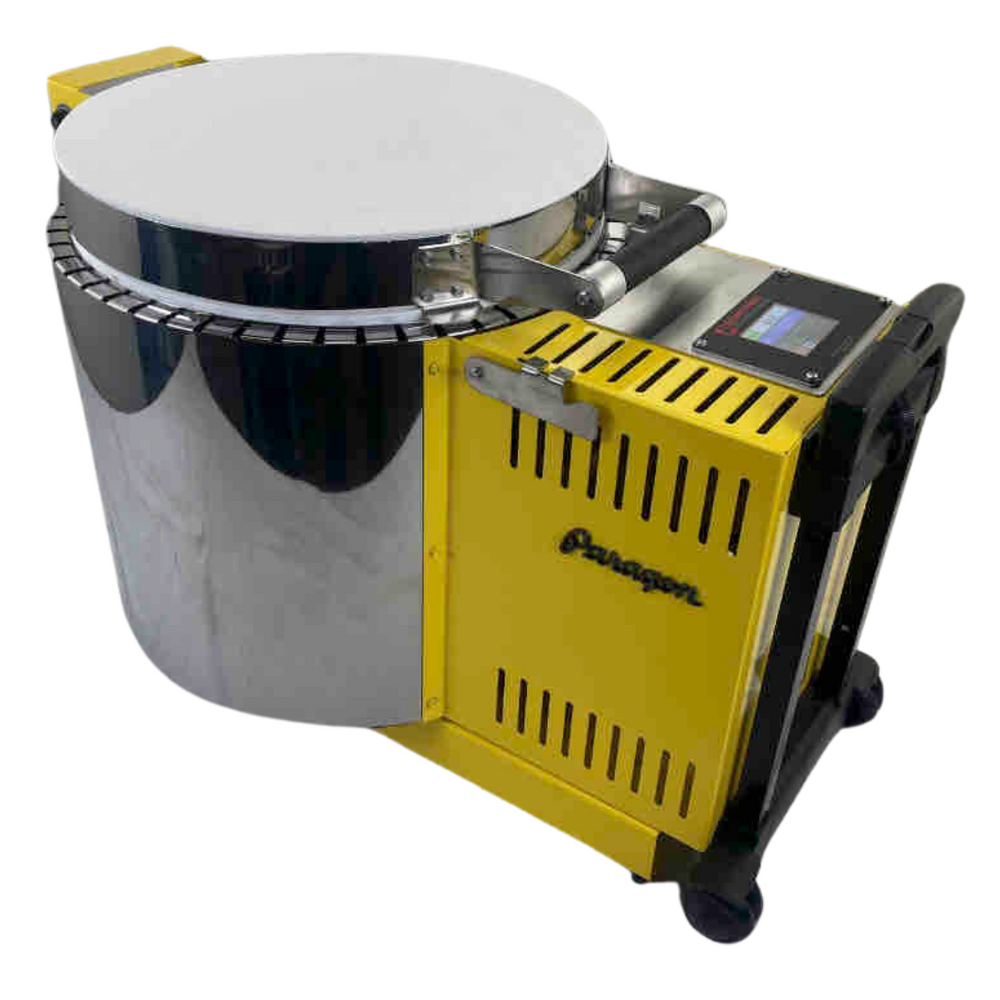

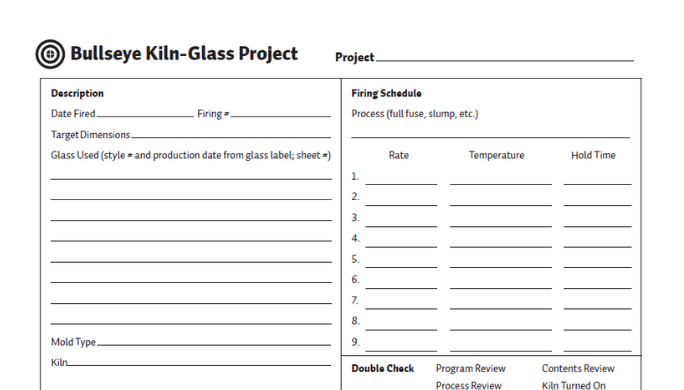

DUAL-MEDIA KILNS are kilns specifically designed for the flexibility of firing ceramics AND glass. Ceramics and glass can be fired in any kiln that achieves the temperature you need. However, this dual design allows the kiln to reach the high firing temperatures of over 2100F needed for glass casting, pottery, and ceramics using the side element, while the lid element used alone is perfect for fusing glass!

KNOW WHAT YOU NEED... Dual-media kilns can be low-fire at 2100F, which means Cone 04-06, medium-fire at 2200F, Cone 06-8; or high-fire rated at 2300-2350F, which means Cone 8-10. It's important to know what type of clay you want to fire before you choose a hybrid kiln so you get exactly what you want.

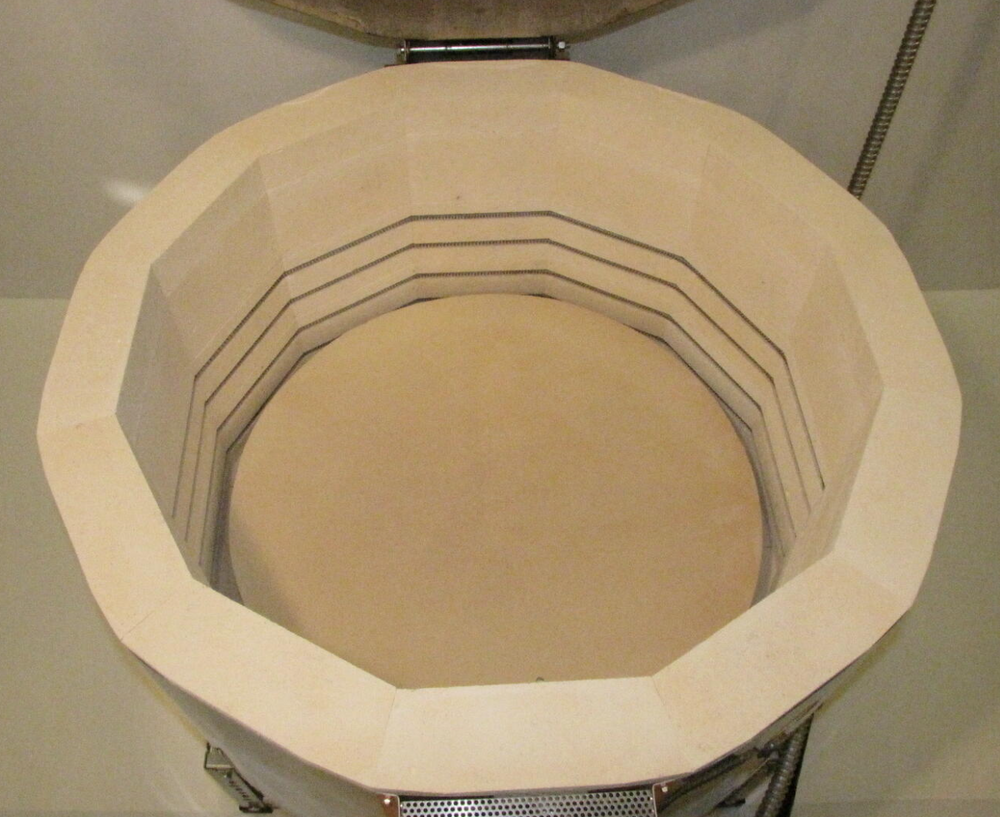

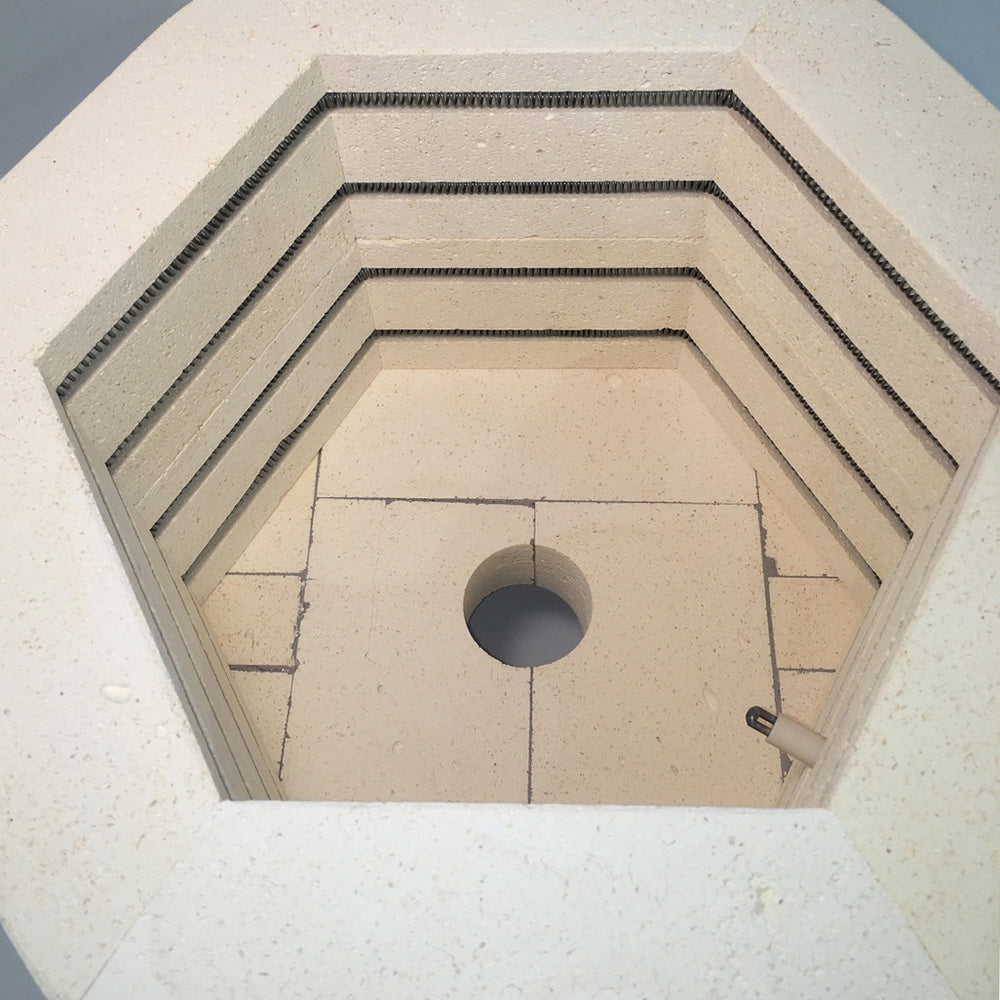

HEAT RISES... When you are using a Dual-Media kiln in ceramic mode, only the side elements are firing, BUT since heat rises, you are continually "heating" the "sleeping" lid element. This high-temperature baking of a "sleeping" element might shorten its lifespan.

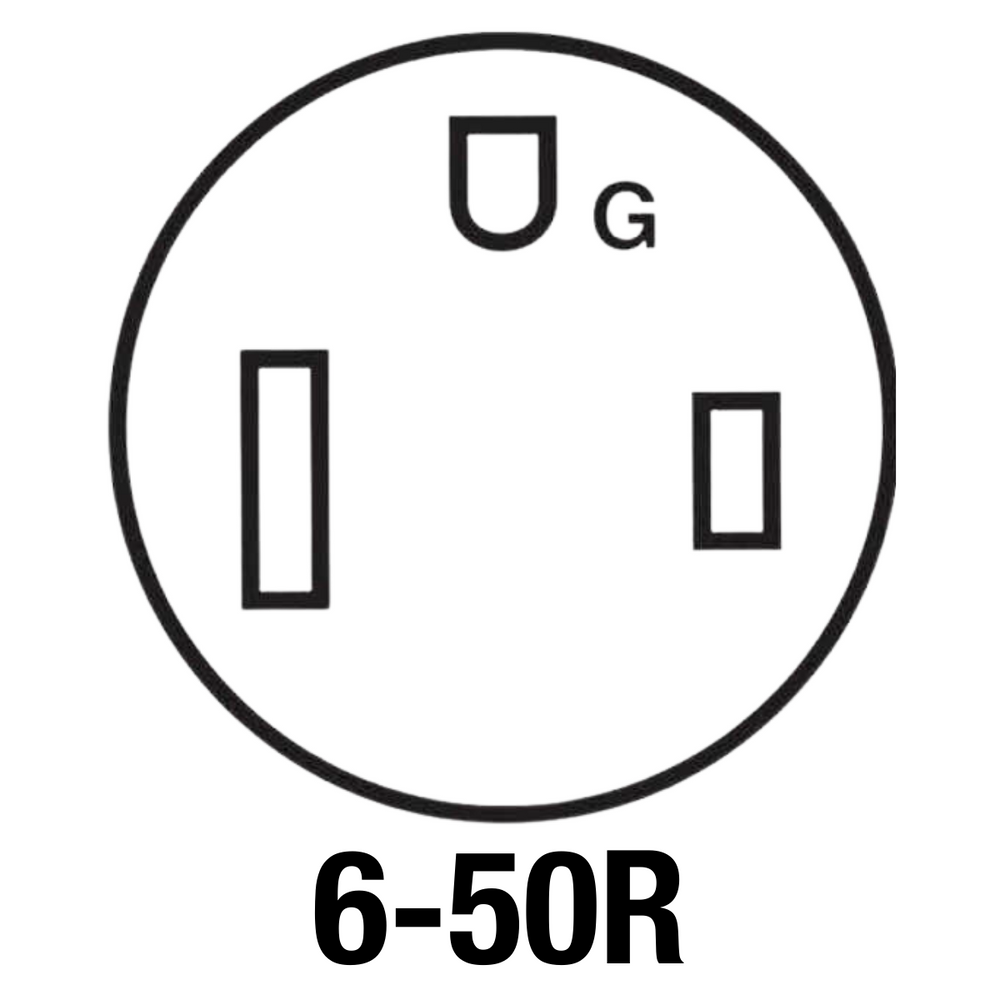

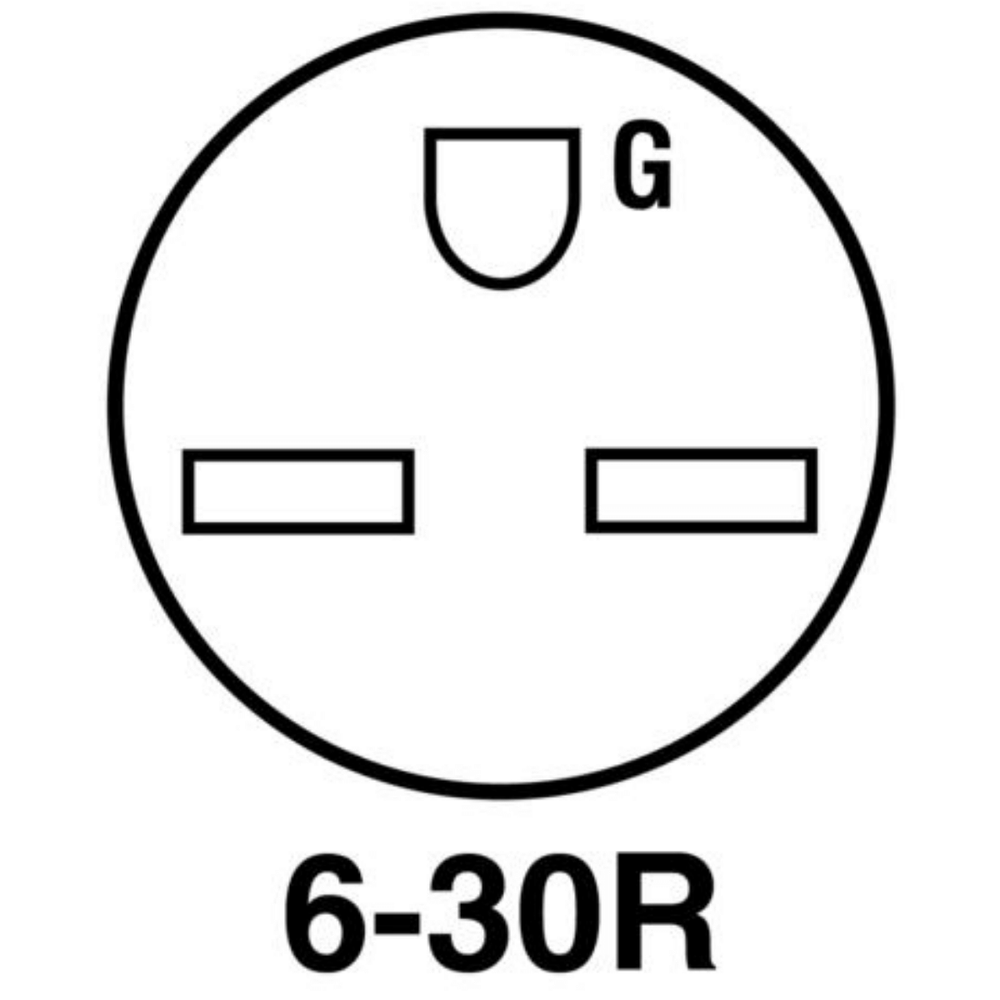

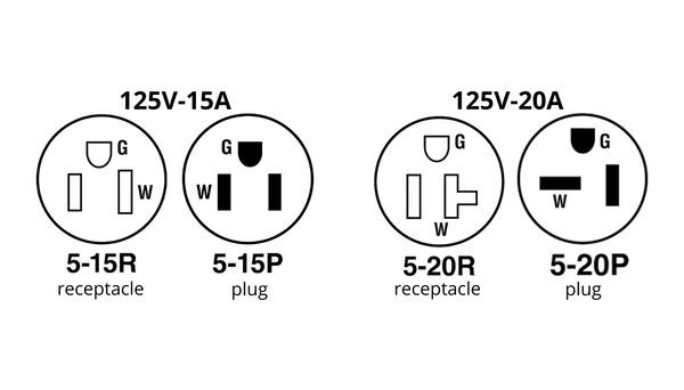

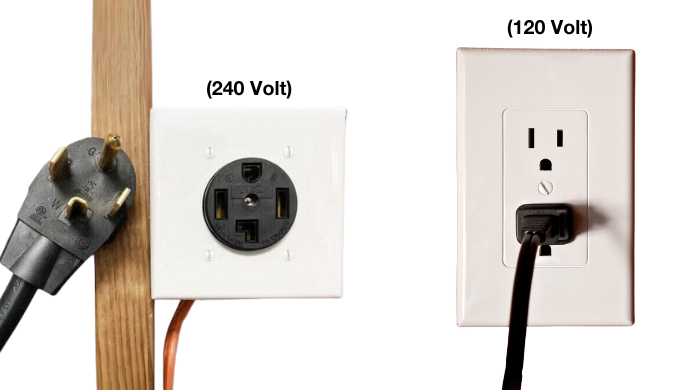

USE OF AMPERAGE... A Dual-Media kiln will use more power in the ceramic mode than in the glass mode.

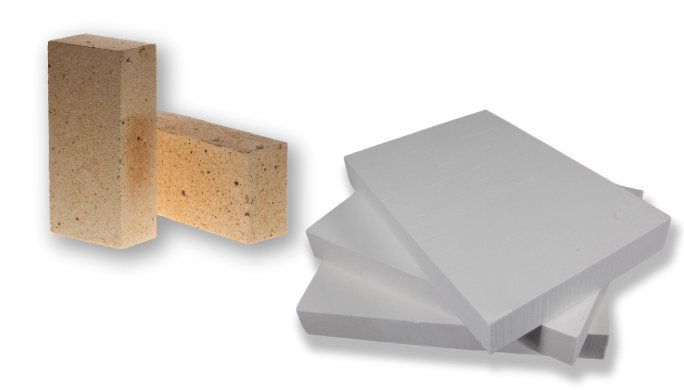

STACKING vs NO STACKING... Dual-Media kilns can hold a lot of stacked shelves when firing clay pieces. The rule for glass is still: one shelf 6–10" from the top element!

Want to know more? Check out this blog post...