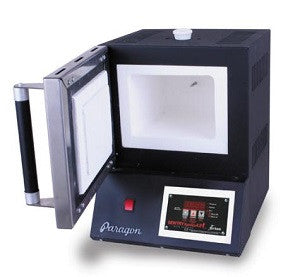

WAX BURNOUT KILN

29 products

29 products

LOST WAX CASTING is the process of carving a shape in wax, making a mold of the wax shape, and then casting that shape into metal from the mold. The mold is a negative image of the wax. The wax is melted out of the mold through hollow channels called sprues. Lost wax burnout is the process of preparing a casting mold for the melted metal that will be poured into it.

THE BURN OUT... All the wax in the mold must then be burned out or melted out of the mold in the kiln. The metal is then melted in the kiln at high temperatures in crucibles and poured into the empty mold to cool.

ALL OF THE WAX BURNOUT KILNS IN THIS COLLECTION are appropriate for the lost wax casting process. But they can also be used as metal clay kilns, enameling kilns, fused glass jewelry kilns, ceramic jewelry kilns, laboratory kilns, or even small folder kilns for bladesmiths. These kilns can be very versatile!

So how do you make your choice? What you really need to know is:

Here is a link to a cool internet guide we found that you can use as a reference: Lost Wax Casting Tutorial and Guide

We're always here if you need a hand finding the right kiln for you! Just give us a call!

Join Our Newsletter

Sign up to receive insider discounts, updates on new arrivals, special offers, and other juicy information.