GLASS FUSING AND CASTING KILNS

162 products

162 products

GLASS FUSING KILNS, glass casting kilns, and glass annealing kilns are designed to fire at temperatures up to 1700F degrees, these lower temps are suitable for most glass projects.

The elements in a glass kiln are placed in the lid of the kiln and may also be placed on the sides. The top elements work to radiate heat onto the face of the glass surface, while the side elements radiate heat throughout the kiln, stabilizing the internal temperature. Having top and side elements in an electric glass kiln for glass fusing and glass slumping keeps temperature differences within a glass project uniform and prevents cracking. Sometimes glass kilns are top-fired only, and based on the size and materials in the kiln, that can be adequate for the heat demand. Finally, glass firing kilns always have a digital controller, allowing for multiple ramp and hold segments for heating, cooling, and stabilizing temperatures throughout the firing process, allowing for a solid annealing schedule to be achieved.

So how do you make your choice? What you really need to know is:

Glass Fusers have specific needs that are different from those of other kiln users. Check out these links to help you make some crucial decisions.

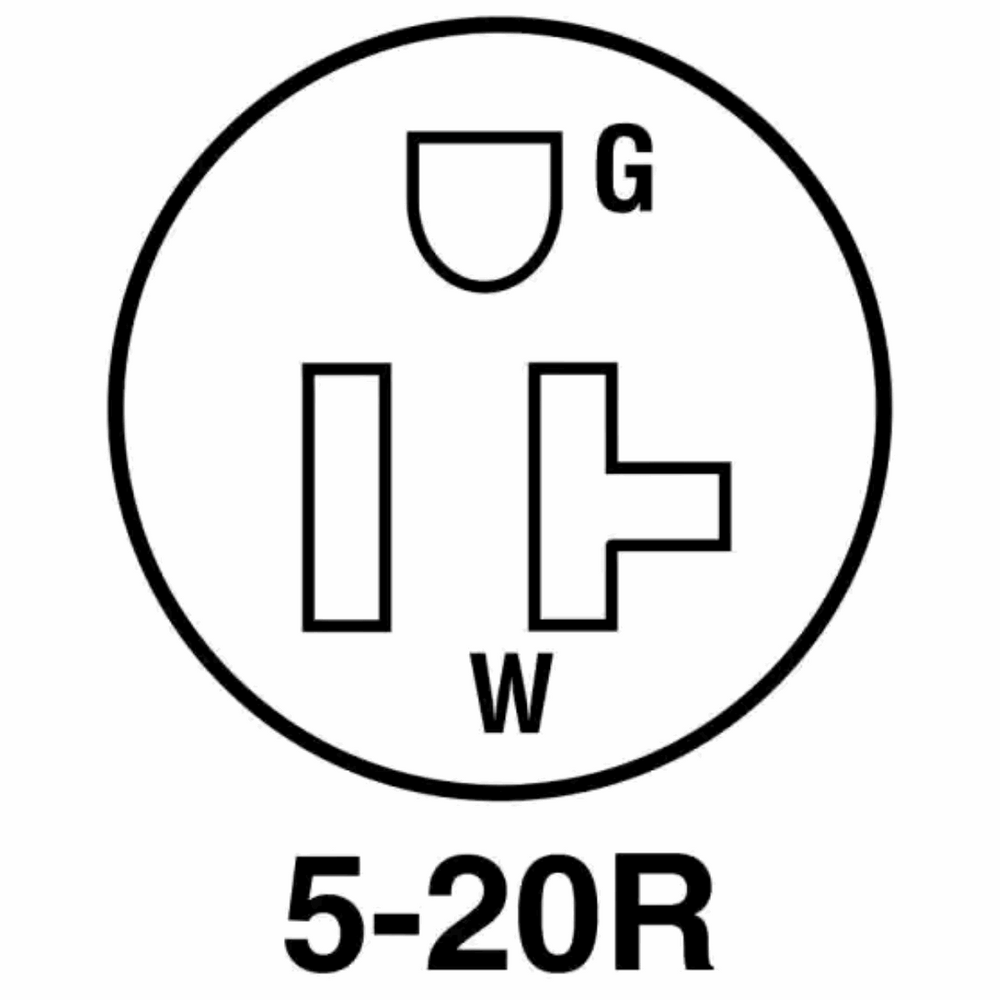

Here's a few that will help: Fiber v Brick , Shape, Size & Depth Considerations , what plug do I need?

We're always here if you need a hand finding the right kiln for you! Just give us a call!

Join Our Newsletter

Sign up to receive insider discounts, updates on new arrivals, special offers, and other juicy information.