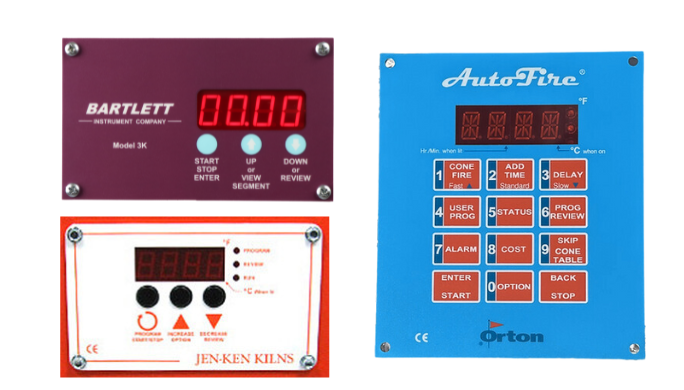

SINTERING OVENS / FURNACES

Sintering is a heating process where powdered materials are compacted into a solid mass by applying heat, but without melting the material to the point of liquefaction. The heat causes the particles to bond at their surfaces, creating a solid piece with improved mechanical properties. At Kiln Frog, we customize solutions to address the unique challenges and opportunities presented by new materials and advanced 3D printing processes.

Key Features of a Sintering Oven/Furnace:

-

Temperature Control/Uniform Heating: Designed to reach and maintain precise high temperatures, ranging from 500F-2400°F, depending on the material.

-

Atmosphere Control: Gas Inlets and Flow Meters introduce inert gases like argon or nitrogen, or reducing atmospheres like hydrogen to prevent oxidation or other chemical reactions.

-

Cooling System: Including slow cooling controls to prevent thermal shock or to achieve specific material properties.