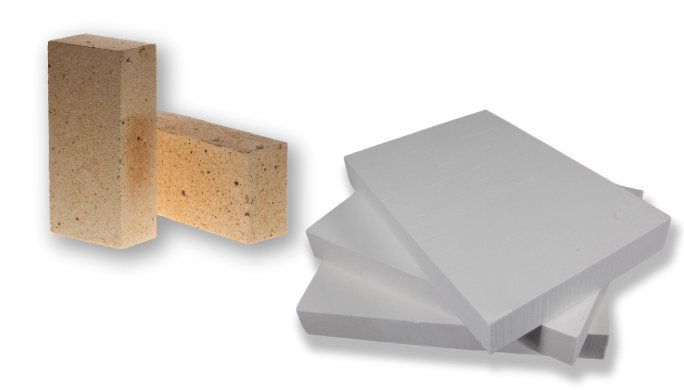

DUAL-MEDIA KILNS are kilns specifically designed for the flexibility of firing ceramics AND glass. Technically speaking, ceramics and glass can be fired in any kiln that achieves the temperature you need. However, this dual design allows the kiln to reach the high firing temperatures of over 2100F needed for glass casting, pottery, and ceramics using the side element, while the lid element used alone is perfect for fusing glass!

HEAT RISES... When you are using a Dual-Media kiln in ceramic mode, only the side elements are firing, BUT since heat rises, you are continually "heating" the "sleeping" lid element. This high-temperature baking of a "sleeping" element might shorten its lifespan. This is not really a big issue as long as you are aware that you may have to change out the lid coil more often than the body coils.

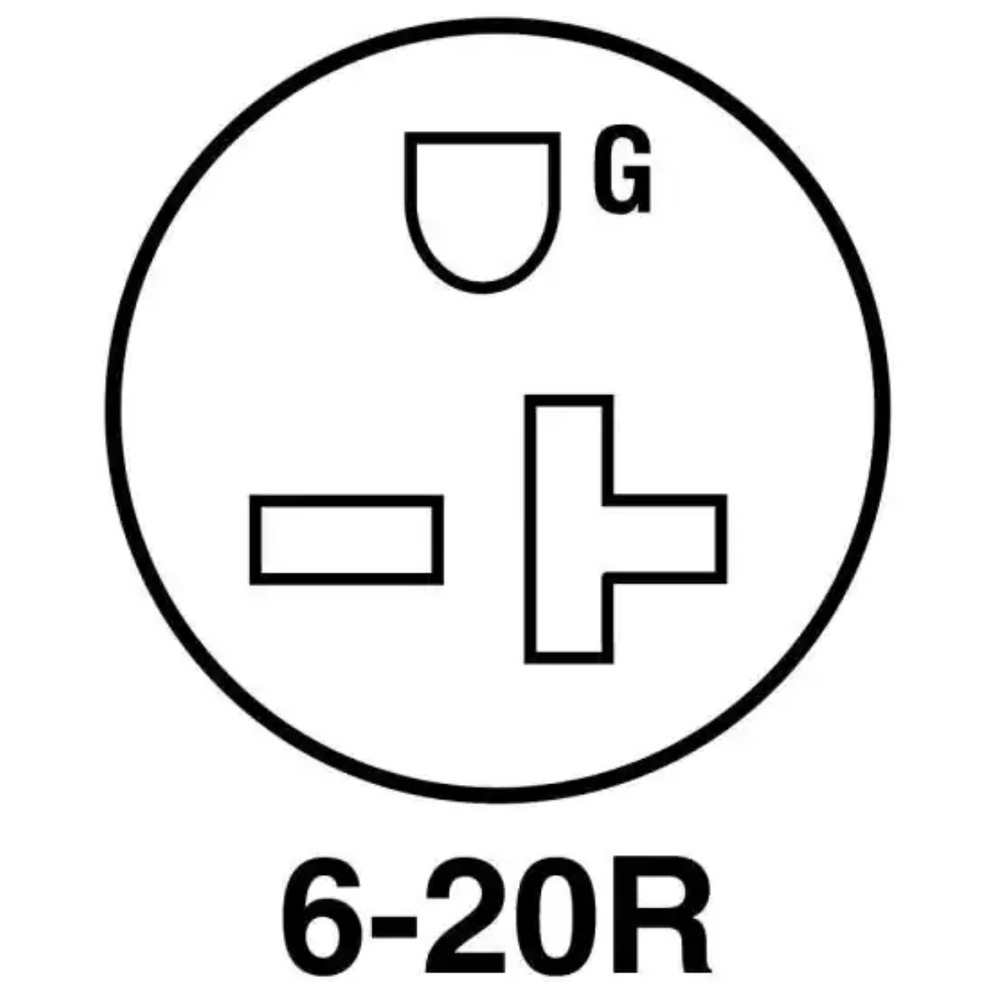

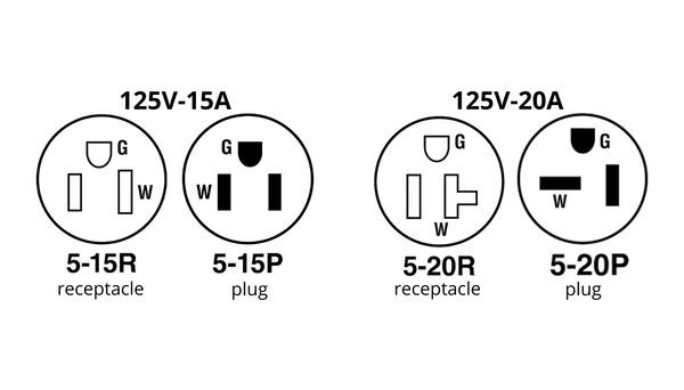

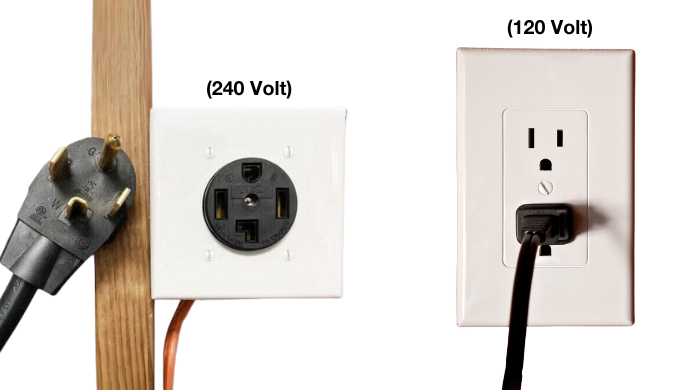

USE OF AMPERAGE... A Dual-Media kiln will use more power in the ceramic mode than in the glass mode. As you know, clay needs to be fired at higher temperatures than glass, so it's just physics that you'll be using more power.

STACKING vs NO STACKING... Dual-Media kilns can hold a lot of stacked shelves when firing clay pieces. BUT just because it can do that in ceramic mode doesn't mean you can do it in glass mode. The rule for glass is still: one shelf 6–10" from the top element! Want to know more? Check out this blog post...

In the end, only you know how much clay vs. glass work you plan to do and if a Dual-Media kiln is the right choice for your studio. As always, if you have questions, call us. We are here to help!