Firebrick

Firebrick Kiln

Firebrick Kiln Repair Kit

Kiln Academy

Kiln Repairs

Kiln Wash

kiln-education

Kilns

Paragon Kilns

Increasing the Life of your Firebrick Kiln

Throughout the years, we have seen 10+ year old kilns with firebricks that are still in pristine condition and relatively new kilns that looked like they had been dropped from a three-story roof. It's pretty easy to tell when a kiln has been cared for and given that extra level of TLC or, what we like to call "KLC"... Kiln Loving Care!

Here are a few tips from Arnold Howard at Paragon Industries on how to give your firebrick kiln that extra Kiln Loving Care:

1. Vaccuuming is a must. Vacuum the kiln interior regularly using the soft brush nozzle of a vacuum cleaner. Be sure to vacuum the element grooves, the inner surface of the kiln lid or roof, and the underside of kiln shelves and be gentle when you touch the firebricks with the nozzle. Vacuuming the grooves is essential if you have had anything explode inside the kiln. Pieces of greenware that lodge inside the grooves can burn out an element. Vacuum the kiln often if you use silica sand on the shelves. The sand, which is used to support ware during firing, can ruin the elements if it filters down into an element groove. As you vacuum the kiln, examine the walls for glass or glaze particles that have embedded into the firebricks. Dig these out carefully. Otherwise the particles will embed deeper into the firebrick during the next firing.

2. Kiln Wash is your friend. Apply kiln wash, liquid kiln coating or glass separator to the kiln’s firebrick bottom. But keep kiln wash away from the walls and elements. On Kiln Frog you can find kiln wash for glass and kiln wash for ceramic.

3. Dry your greenware. If possible, do not fire moist greenware. It should be bone-dry and warm to the touch. If you must fire moist greenware, wait until all signs of vapor have disappeared before heating past 200 degrees F. The moisture at higher temperatures is not good for the firebricks and can cause the greenware to explode.

4. Be gentle. Lower the kiln lid (or close the kiln door) gently. Slamming the lid can crack the lid the first time it happens. Fully disengage the lid support before lowering the lid. Forcing the lid downward can break the bricks near the lid hinge. From time to time, check the condition of the lid support.

5. Keep closed. Keep the lid closed when you are not using the kiln. This keeps dust out and prevents the lid from dropping while you are away from the kiln. Do not store anything inside the kiln.

6. Level it. The kiln stand should be level and rock-steady. An unleveled stand can stress the firebricks. A stand that rocks can cause the kiln to move when jarred, knocking over ware against the sidewalls inside the kiln.

7. Don't lean on me. Do not lean too heavily against the firebrick walls while loading and unloading. Some people use a small stepladder to reach into a deep kiln. You can also cut a piece of plywood to fit across the wall that helps protect the wall during loading.

8. Try not to touch. During loading and unloading, do not touch the sidewalls of the kiln with anything. Do not allow a shelf to bump into the firebricks. The extra time and care you spend loading and unloading may add years of life to your kiln.

Here are a few tips from Arnold Howard at Paragon Industries on how to give your firebrick kiln that extra Kiln Loving Care:

1. Vaccuuming is a must. Vacuum the kiln interior regularly using the soft brush nozzle of a vacuum cleaner. Be sure to vacuum the element grooves, the inner surface of the kiln lid or roof, and the underside of kiln shelves and be gentle when you touch the firebricks with the nozzle. Vacuuming the grooves is essential if you have had anything explode inside the kiln. Pieces of greenware that lodge inside the grooves can burn out an element. Vacuum the kiln often if you use silica sand on the shelves. The sand, which is used to support ware during firing, can ruin the elements if it filters down into an element groove. As you vacuum the kiln, examine the walls for glass or glaze particles that have embedded into the firebricks. Dig these out carefully. Otherwise the particles will embed deeper into the firebrick during the next firing.

2. Kiln Wash is your friend. Apply kiln wash, liquid kiln coating or glass separator to the kiln’s firebrick bottom. But keep kiln wash away from the walls and elements. On Kiln Frog you can find kiln wash for glass and kiln wash for ceramic.

3. Dry your greenware. If possible, do not fire moist greenware. It should be bone-dry and warm to the touch. If you must fire moist greenware, wait until all signs of vapor have disappeared before heating past 200 degrees F. The moisture at higher temperatures is not good for the firebricks and can cause the greenware to explode.

4. Be gentle. Lower the kiln lid (or close the kiln door) gently. Slamming the lid can crack the lid the first time it happens. Fully disengage the lid support before lowering the lid. Forcing the lid downward can break the bricks near the lid hinge. From time to time, check the condition of the lid support.

5. Keep closed. Keep the lid closed when you are not using the kiln. This keeps dust out and prevents the lid from dropping while you are away from the kiln. Do not store anything inside the kiln.

6. Level it. The kiln stand should be level and rock-steady. An unleveled stand can stress the firebricks. A stand that rocks can cause the kiln to move when jarred, knocking over ware against the sidewalls inside the kiln.

7. Don't lean on me. Do not lean too heavily against the firebrick walls while loading and unloading. Some people use a small stepladder to reach into a deep kiln. You can also cut a piece of plywood to fit across the wall that helps protect the wall during loading.

8. Try not to touch. During loading and unloading, do not touch the sidewalls of the kiln with anything. Do not allow a shelf to bump into the firebricks. The extra time and care you spend loading and unloading may add years of life to your kiln.

9. Always look for drips. If glaze, glass, or other materials drip onto a kiln wall or the kiln bottom, repair before the next firing. Otherwise these materials will remelt and embed deeper into the firebricks. Remove the contaminant by scraping gently with a putty knife. If you remove kiln wash from the kiln bottom, apply a fresh coat to the bare spot.

10. Don't worry! Do not be concerned about small cracks that appear in the firebricks. The cracks are normal and act as expansion joints. During firing, they close tightly.

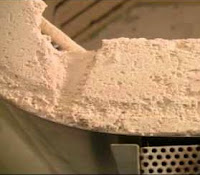

Finally, if a firebrick edge breaks off, don’t stress. The damage is usually slight and does not affect the firings, and can easily be repaired with our Firebrick Kiln Repair Kit.

Finally, if a firebrick edge breaks off, don’t stress. The damage is usually slight and does not affect the firings, and can easily be repaired with our Firebrick Kiln Repair Kit.

Leave a comment