Featured product

Popular posts

You may also like

- All Collections

- Tool & Equipment

- Kilns

- metal forge

- mini forge

- anvil stand

- Small forge

- Supplies

- Brand

- Accessories

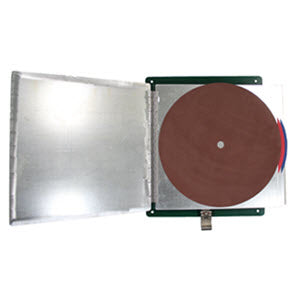

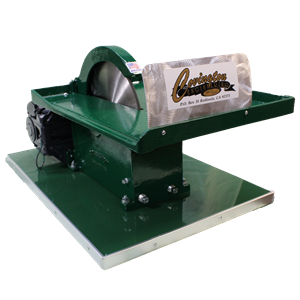

- Glass Saw

- Rock Saw

- Lapidary Saw

- Slab saw

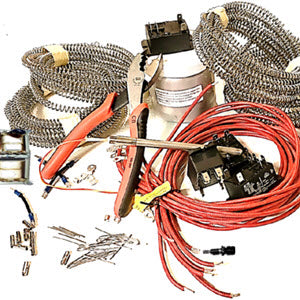

- Parts

- Metal Band Saws

- Vertical Saw

- belt grinder

- belt sander

- metal grinder

- metalworking equipment

- grinding belts

- quench tank

- metal clamp

- bench vise

- drill press

- equipment stand

- rock tumbler grit

- Raku

- Cermic Kilns

- Pottery Kilns

- lapidary tumbler

- jewelry tumbler

- stainless steel shot for tumbler

- tumbler shot

- KILN SHELVES

- KILN SHELF KITS

- KILN FURNITURE

- KILN POSTS

- Sintering Ovens

- Sintering Furnaces

- Powder Metallurgy

- Additive Manufacturing

- 3-D Printing

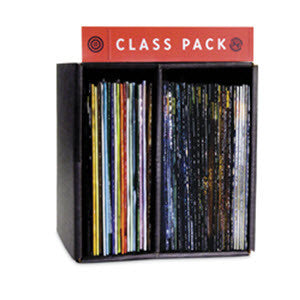

- Books

- Video

- E-Book