AN ALL NEW DESIGN FOR 2024!!

The GTS 41 is a premier top-loading kiln crafted with the glass artist in mind. Designed to provide ample space without the weight and potential residue of a firebrick lid, this kiln features a unique combination of a fiber lid and firebrick chamber. Offering the best of both worlds, it stands as Evenheat’s largest and most popular top-loading glass kiln, catering to the needs of all glass artists.

| Model: | Evenheat GTS 41 |

| Inside Dim: | 25.25" (depth) x 40.5" (width) x 13.5" (height)* |

| Outside Dim: | 30.25" (depth) x 56" (width) x 29.5" (height)* |

| Shelf Size: | 39.3"(wide) x 24"(deep) x 1" Full Shelf - NOT INCLUDED |

| Max Temp: | 1800° F |

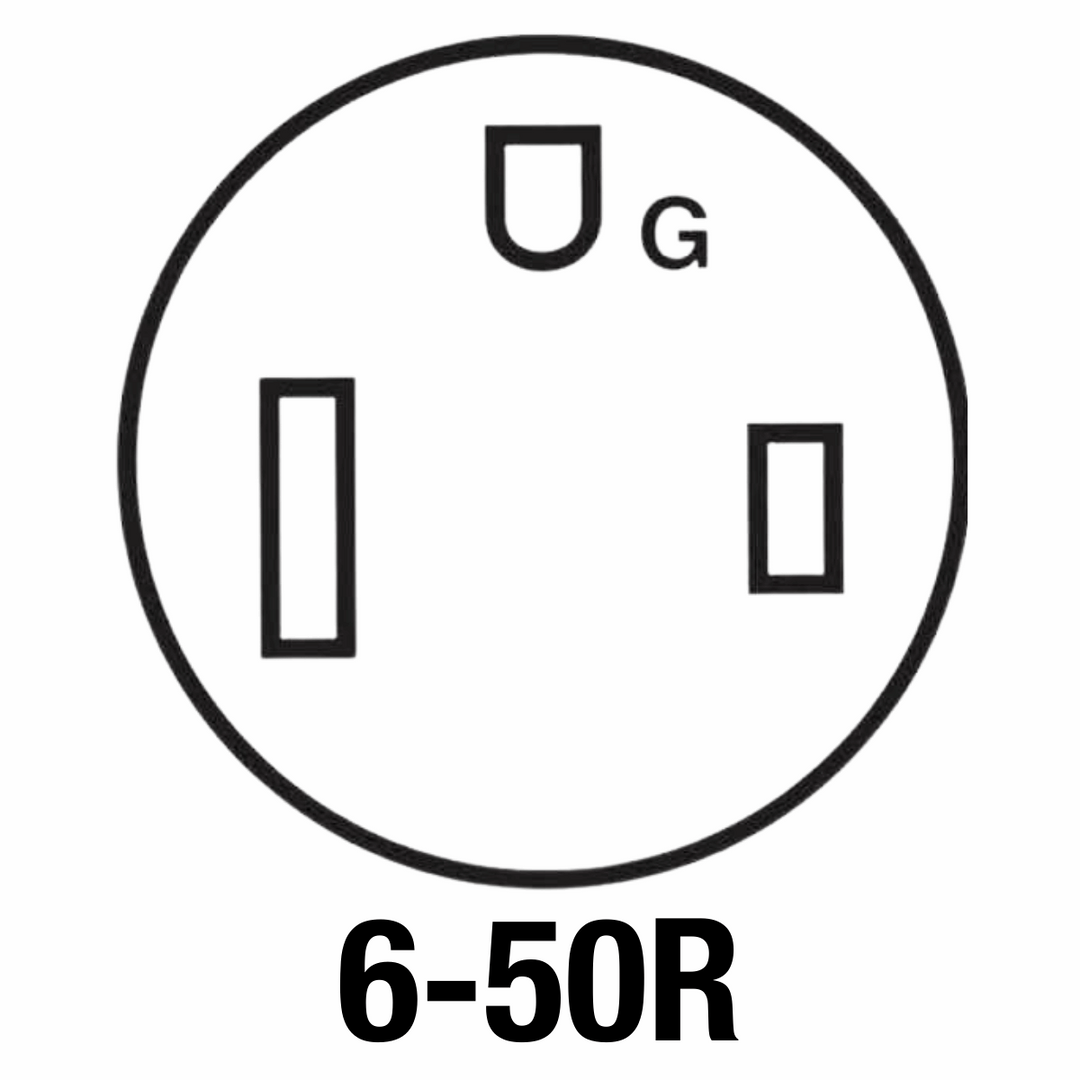

| Voltage: | 240 volts |

| Amperage: | 45 amps |

| Watts: | 10,800 watts |

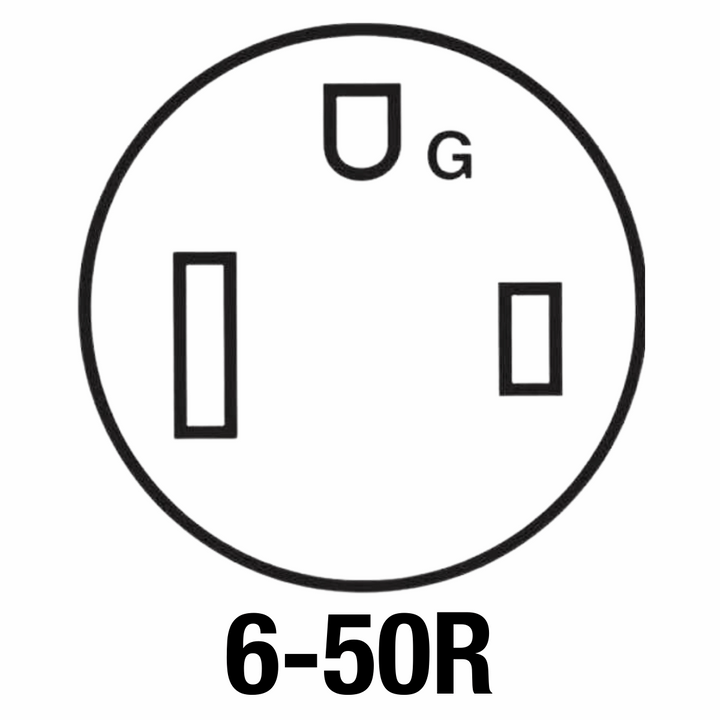

| Receptacle: | 6-50R |

| Ship Wt: | 365# (freight) |

Includes:

- FREE SHIPPING in the contiguous US!

- Icon+/Genesis Touchscreen Controller

- Top and Side Fire Configuration

- Fiber Lid Construction

- Swing View Adjustable Control (RM and Tap Controllers)

- Wide Lid Handle

- Power Interrupt Switch

- Full Stainless Jacket

- Large Size

- Responsive Thermocouples

- Excellent Temperature Distribution

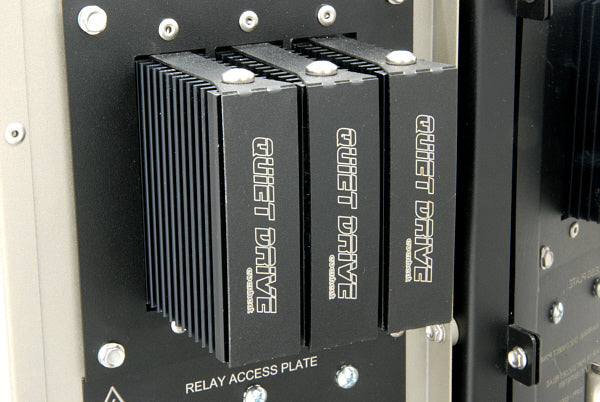

- Solid-State Relays Standard - NEW!

- 2-Year Limited Warranty (The manufacturer's warranty as well as the optional add-on Extended Warranty Protection Plan do not cover a service contractor to provide in-home kiln repairs.)

- * Width refers to the side to side measurement, depth to the front to back measurement, and height to the bottom to top measurement of the kiln.

All this and more in a design that looks as good as it performs.

NEW! Better Venting Options! Evenheat now offers a Two-Position Lid Vent. The lower vent position props the lid up by about an inch. Perfect for venting off adhesives and other low-temperature binding materials. The upper vent position props the lid by about 4 inches. Perfect for speeding up the cooling process.

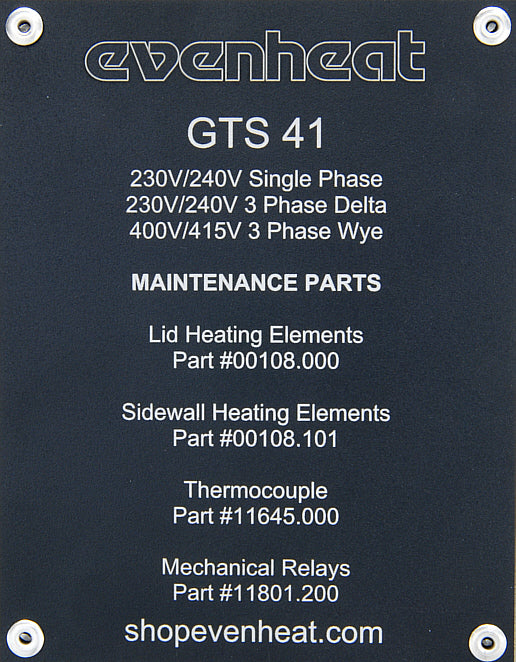

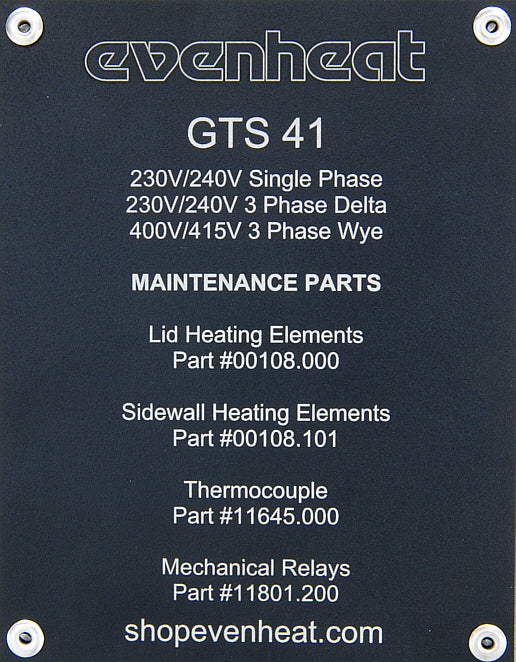

NEW! An easily identifiable Maintenance Tag! To assist you in replacing worn items we have included a maintenance parts tag on the GTS 41 indicating the proper Evenheat part numbers for anticipated maintenance items. Wish we had this decades ago.

All these improvements build on the legacy of what artists have come to expect from GTS line.

Fiber and Firebrick Design: The GTS 41 features a unique construction, blending fiber and firebrick materials for superior performance. Its lid, entirely fiber-based, not only reduces weight but also prevents loose firebrick particles from affecting your glass creations.

Meanwhile, the walls and floor are crafted from firebrick, ideal for glass kilns due to its heat retention properties. This ensures consistent temperature control throughout the firing process, resulting in impeccable annealing and stunning results. Just like the Studio Pro line, the GTS 41 combines these exceptional materials to deliver one of the top kilns on the market.

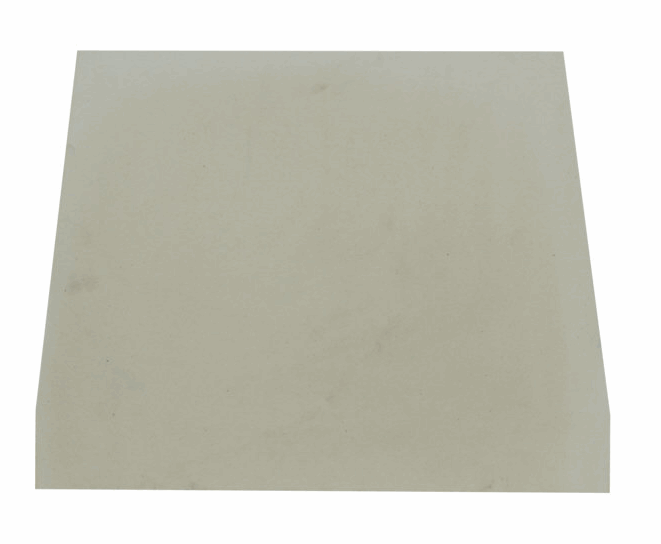

Fiber Lid Construction: The lid of the GTS 41 is constructed of a fiber material that provides excellent thermal properties along with a light weight. This design allows the heating elements to be positioned on the surface for maximum heat transfer and firing efficiency. The fiber chosen for the lid is an extremely low-shot material. The surface is then covered with a no-shot fiber sheet. These two materials combine to create a lighter-weight lid while severely limiting any debris from the lid falling onto the glass. Very nice.

Lift Assisted: To assist in chamber opening, the GTS 41 includes a spring lift assist feature. This well-designed mechanism travels cleanly and securely and causes the chamber to rest easily in the open position. In the heat of battle, you need smooth and anxious-free movement, and the GTS 41 spring lift assist delivers.

Swing View Equipped: The GTS 41 comes equipped with temperature controls integrated into a innovative Swing View Adjustable Enclosure. This pivoting, swing-up enclosure allows you to effortlessly rotate the controls to your preferred viewing and programming angle. Once you've completed your adjustments, simply lay it back down for easy visibility from across your studio. The Swing View feature seamlessly complements touchscreen controls like the TAP II, Icon+, and Icon, ensuring perfect alignment of the viewing angle. It's a convenience you're sure to appreciate.

Power Interrupt Switch Equipped: The GTS 41 is standard equipped with a power interrupt switch that removes electrical power from all heating elements if either the lid or chamber is opened. This is important for those who may access the kiln during firing, such as through glass manipulation and roll-ups.

Relay Access Port: The GTS 41 is equipped with a convenient Relay Access Port, designed for hassle-free relay replacement without the need to remove any panels. Simply remove the access plate to gain direct access to the mechanical relays. No need to remove the control panel or deal with internal wiring—just a straightforward process with a screwdriver. Considering the eventual likelihood of mechanical relay failures, this access port proves to be a great feature that offers ease and efficiency in maintenance tasks when they arise.

OPTIONS:

TAP, Icon, Icon+ or Rampmaster III Controls Option: The GTS 41 is available with your choice of the TAP, Icon or Icon+ temperature controllers. The TAP, Icon and Icon+ are touchscreen-style and offer full programming functions. While Rampmaster III is a 12-key digital controller is a great alternative for those who don’t want a touchscreen.

Rolling Option: The GTS 41 is easily made mobile with our rolling option. The GTS 41 base is equipped to accept our casters. No frame or extra hardware is required. Simply attach the casters to the standard base, and you're ready to go! Casters are not factory-installed. You will install them when you first set up your kiln. It's designed to be easy, and it is. They can always be added later as well.

Why upgrade from Mechanical Relays to Solid-State Relays? Mechanical Relays, which come standard on most kilns have internal moving parts which over time wear out and need to be replaced. Kiln manufacturers recommend you replace your mechanical relays approximately every 2 years. Solid-state relays have no moving parts and last far longer than standard mechanical relays and offer far better temperature control during hold times. Since solid-state relays also have no moving parts to wear out, they NEVER need to be replaced. You will notice that solid-state relays are silent. The only sound you will hear is just the reassuring hum of the heating elements. So, this factory upgrade saves you potential down time from having to wait for new relays to arrive, potential over-fires from relays sticking in the closed position, potential aggravation from having to learn how to remove and replace the mechanical relays yourself. We think this upgrade is well worth the cost and will save you time and aggravation over the life of your kiln.

Enjoying the kiln and will probably be even better when we speak with Jim and Evenheat next week about getting rid of flickering light fixtures in the studio since this kiln was installed. Has to have something to do with the SSRs.

Art Banks

Hello Arthur,

We are glad you enjoy your kiln. Jim at Evenheat is great! I hope there is a simple solution for the flickering lights. Thanks for sharing your feedback! We appreciate your input. If you have more details or suggestions, feel free to reach out at customerservice@kilnfrog.com or via phone 361-596-3764.

Join Our Newsletter

Sign up to receive insider discounts, updates on new arrivals, special offers, and other juicy information.

KILNS SHIP FREE IN THE US 48*

BEST PRICE

GUARANTEE