-

Kiln Types

Ceramics / Pottery Kilns Porcelain / China Kilns Raku Kilns (Electric & Gas) Dual Media Kilns (Glass + Ceramic) Annealing Kilns Glass / Glass Casting Kilns Vitrigraph Kilns Crucible Kilns / Furnaces Enameling Kilns Wax Burnout Kilns / Ovens Knife / Heat Treat Ovens / Kilns Metal Clay Kilns Industrial Kilns / Ovens / Furnaces Sintering Ovens / Furnaces DPF Thermal Cleaning Furnaces - Kiln Finder Quiz

-

- READY-TO-SHIP KILNS / OVENS IN INVENTORY

-

- Ceramics / Pottery Kilns

- Porcelain / China Kilns

- Raku Kilns (Electric & Gas)

- Dual Media Kilns (Glass + Ceramic)

- Annealing Kilns

- Glass / Glass Casting Kilns

- Vitrigraph Kilns

- Crucible Kilns / Furnaces

- Enameling Kilns

- Wax Burnout Kilns / Ovens

- Knife / Heat Treat Ovens / Kilns

- Metal Clay Kilns

- Industrial Kilns / Ovens / Furnaces

- Sintering Ovens / Furnaces

- DPF Thermal Cleaning Furnaces

- Kiln Finder Quiz

****ON BACK ORDER UNTIL AUGUST 2025****

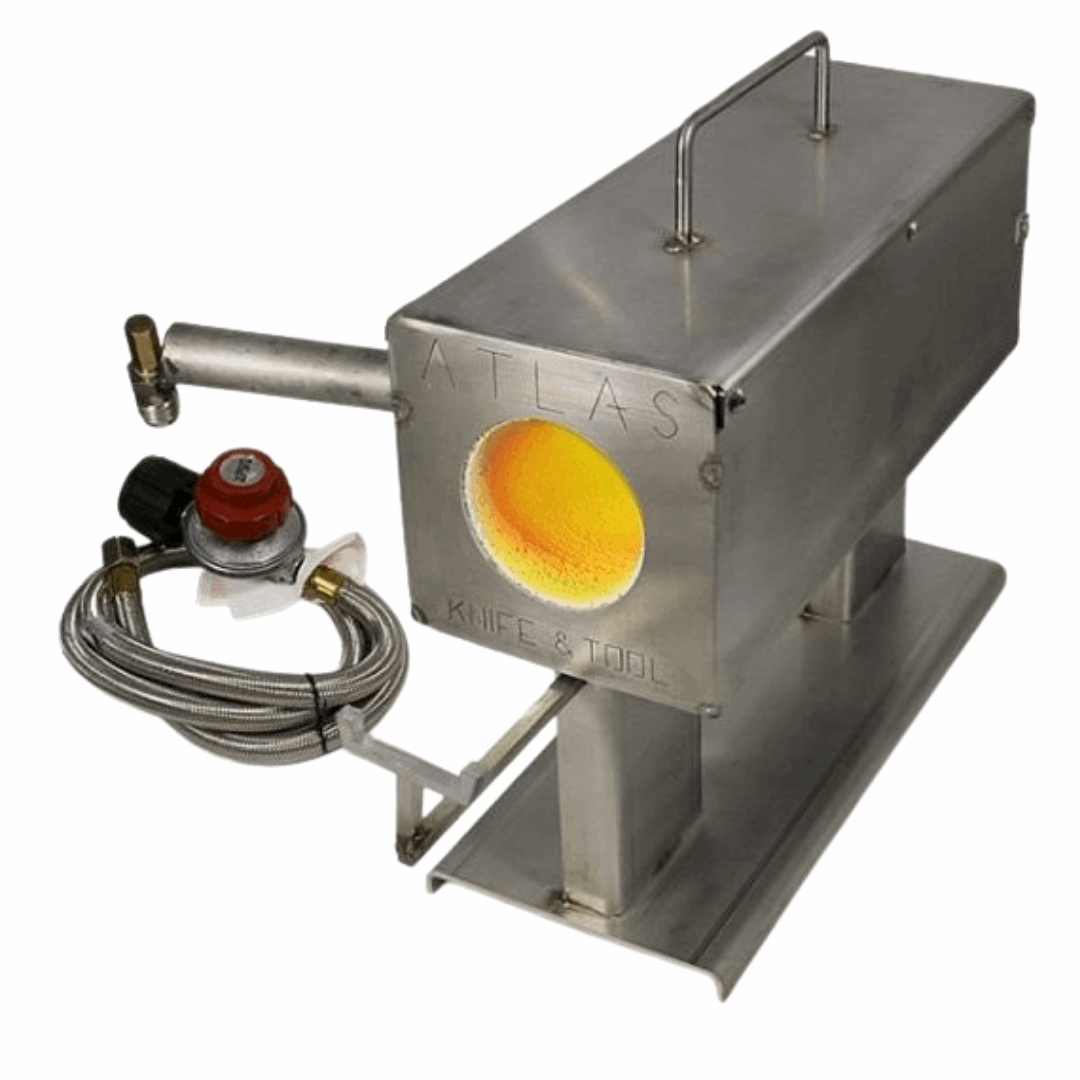

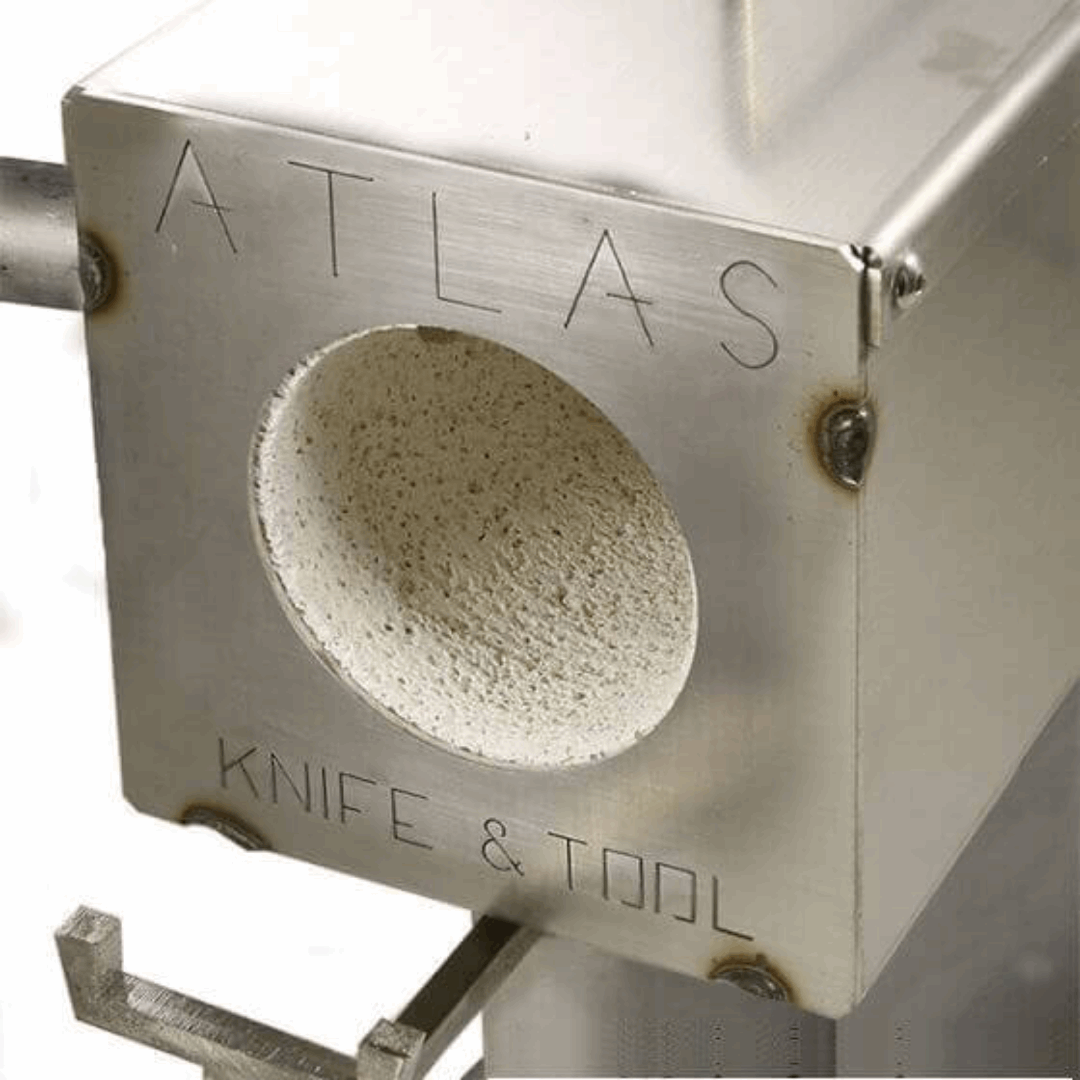

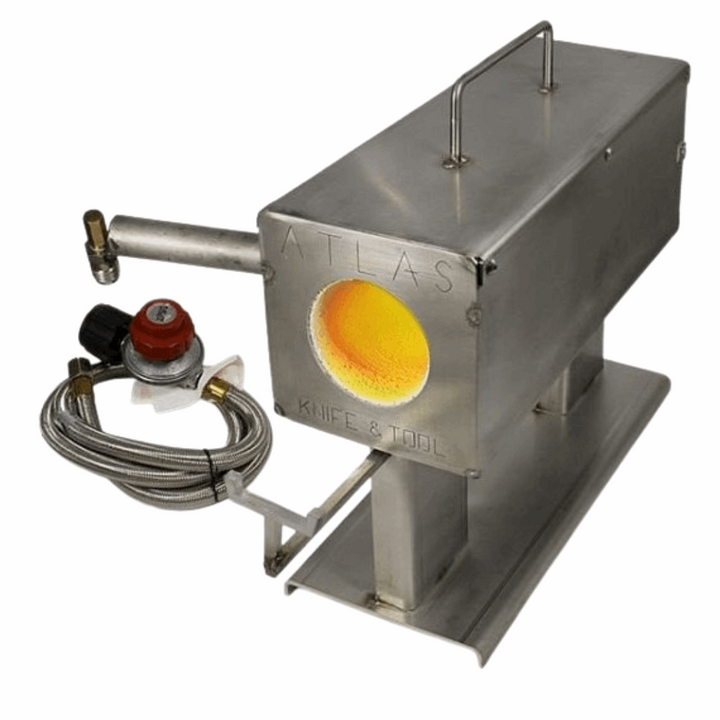

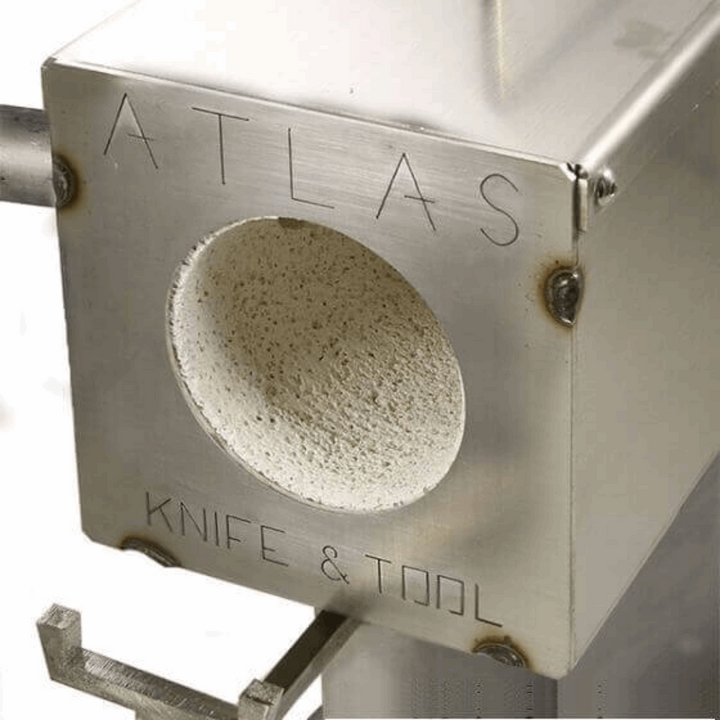

The best forge for bladesmithing! This forge will get hotter and its insulation will last longer than most, it won’t rust, and it only uses $1 propane per hour! Top that off with a swirling chamber, and it is believed to be the ultimate bladesmithing forge. This well engineered forge is very popular amongst schools and even ABS Mastersmiths have been known to add them to their shops.

- Dimensions: 12 x 12 x 6

- Chamber measures 2.5″ diameter × 11″

- 2” rear opening

- Max temp of 2500° F

- 630+ BTU per cubic inch,

- Hot enough to forge weld!

- Weight: 19.8 lbs.

- 1 Year Limited Warranty (Refer to Manufacturer's Warranty)

- FREE SHIPPING in the contiguous US!

- Stainless steel forge w/ adjustable sliding tool rest

- 0-20 PSI regulator w/hose connects to 20lb. propane tanks

- Atlas stainless steel 30k BTU burner

- 6 oz Plistix 900f (small bag of white powder)

- Plistix 900f can be used to improve your forge chamber but is not required. To apply,

- Spray the inside of your chamber with a mist of water

- Mix Plistix 900f with a small amount of water (I use a small blender)

- Coat the inside of your chamber (I use a spatula or brush)

- Visit the Plibrico website here for more information about Plistix 900f.

The Atlas forge uses Kastolite 50-25 Plus cast refractory, cured and baked for 6 hours at 450°F. Ready to use right out of the box and it will last much longer than wool-based forges.

May include a small bag of Plistix 900F refractory. This can be mixed and painted on the inside chamber to improve the efficiency and toughness of the chamber. NOT REQUIRED FOR USE.

It’s more than hot enough to forge weld, but you need to use a fluxless method. Borax will damage the refractory.

Join Our Newsletter

Sign up to receive insider discounts, updates on new arrivals, special offers, and other juicy information.

KILNS SHIP FREE IN THE US 48*

BEST PRICE

GUARANTEE